Freedom

Get to more places quicker and efficiently, without airport lines or long, tiring drives.

Opportunity

More jobs, more ability to travel, more ways to cleanly transform the economy of the country.

Prosperity

See family and friends across the country. Do business in person. Live life to the fullest.

A Cleaner, More Just Way To Connect

Reduce gridlock and pollution while connecting more communities to the national economy.

Why High Speed Rail?

High speed rail is a realistic, easy, and affordable way to travel that all Americans should enjoy. Here’s why you should demand high speed rail in your region.

- Cleaner travel

- Less gridlock

- Easier than flying

- More efficient

- Unites communities

Two Big Projects are Underway

San Francisco – Los Angeles

California is building a new high-speed line that will link the Bay to the Basin in three hours or less.

Las Vegas – LA Basin

Brightline West is poised to break ground on a new line that will allow travelers to bypass the congestion on I-15.

You can help spread this success across the rest of the country as a member of the High Speed Rail Alliance.

Go Further, Go Faster

High Speed Rail Can Transform the Country

Fast, frequent and affordable trains are about the uniting promise of travel. They are about updating our infrastructure to provide more opportunities. And it’s about bringing us together as one country, connected by rail, and sharing a dream.

When we work together, we can accomplish big things. Let’s get on track.

Great Gift Ideas!

Need a gift for the high-speed rail advocate in your life? (Or yourself?) Here are several items that might do the trick. Make a donation and you will be prompted to pick a gift of your choice!

The Integrated Network Approach allows French high-speed trains to serve stations far beyond the high-speed lines, like the 1922-built station at La Rochelle. Photo: Rick Harnish

Better tracks, better trains and a big-picture plan

Integrated Network Approach

The Integrated Network Approach combines the transformative power of dedicated high-speed lines with the geographic coverage of shared-use lines.

Used across the world, it delivers steady and incremental progress, guided by a long-term plan.

A NATIONAL Railroad Expansion Program

Connecting America will require different types of trains (and buses and planes) working together to serve thousands of communities, big and small.

That means a national program guided by an integrated plan with:

- 20% new high-speed lines

- 80% existing lines upgraded for faster, more frequent, passenger and freight trains.

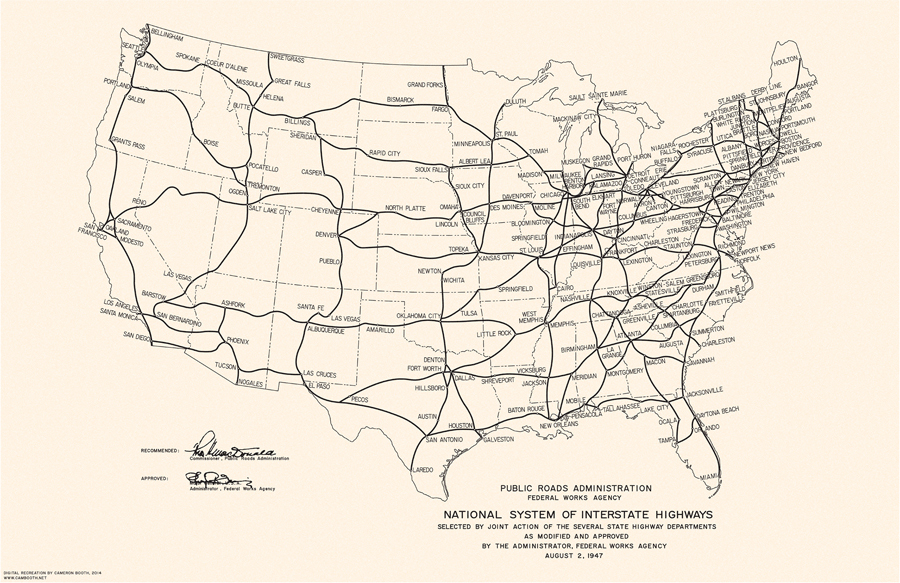

The USDOT should develop a nationwide, integrated rail plan. Just like it did for the Interstate Highway network in 1947.

We rode the first 110-mph train bound for St. Louis

Amtrak, IDOT, and the Union Pacific did a “soft launch” of full 110 mph service on the Chicago – St. Louis Corridor on May 3rd.

We need to celebrate this important milestone while recognizing that much more needs to be done.

Passing traffic on I-55 on the Chicago – St. Louis Corridor.

Sign Our Petition!

Tell Congress to keep building towards a national rail program.

Get Connected, Get Involved

High speed rail benefits everyone — and it will take us all working together to make it a reality. Here are some ways you can bring fast, frequent, and affordable trains to your community and the country.

Join The Community Of Passionate People

At the High Speed Rail Alliance, we’re building something. We’re connecting people who want to connect the country. Through education, activism, and action, we’re bringing together people who understand the promise of high speed rail and want to make it a reality.

Getting engaged is easy — just sign up and start learning.

We’re in this together. We’re a community who wants to help every community, and strengthen the country.

Get Active for High Speed Rail Your Community

Signing petitions. Giving presentations. Talking to leaders, and becoming a leader yourself. The high speed rail community needs people who are ready to step up to created cleaner, better transportation. We’re here to help you take the actions you want.

There are a lot of ways to learn — find out more.

Remember, no important job is easy. We’re all in this together to support each other and change the way we move.

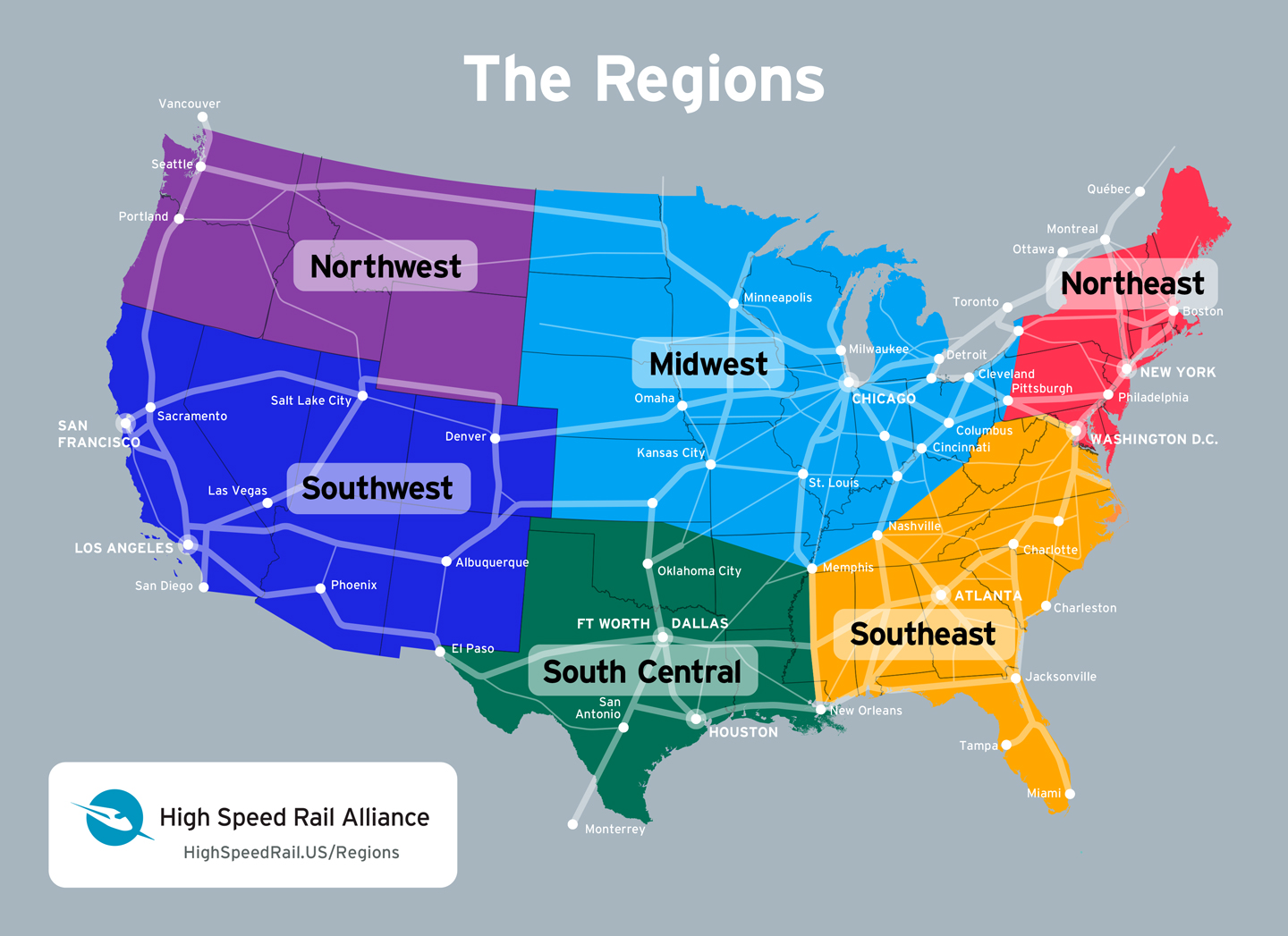

Transform Your Region

High speed rail can connect the country, one region after another.

See what proposals and projects are happening in your area, and what you can do to make them a reality.

The Latest from HSRA

Our Latest Blog Posts

Check out the latest news, updates, and high speed rail insights from our blog!

It’s a Beautiful Country

Let’s see it. Let’s clean it. Let’s build it. Let’s make high speed rail a reality.